Technology

There is a right printing technique for every job. We use flexo and digital printing. We choose the right technique based on the customer’s project. Each printing technique has its benefits. We provide cost-efficient flexo printing for large batches and digital printing for smaller batches.

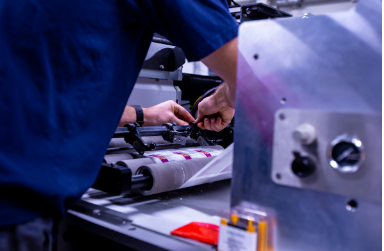

Flexo printing

We use flexo printing machine for wrap around labels that are wrapped around the bottle with the ends of the label glued together. Flexo printing is also suitable for printing various self-adhesive labels. This is a cost-effective method for handling large batches.

Digital printing

Digital printing offers various possibilities for printing labels. The print material is entered into the printer in digital format, no plates are necessary. Low initial costs make this technique suitable for printing constantly changing information in small batches.

Flexo or Digital printing?

Flexo

- Cost-effective method for handling large batches

Digital

- Fast delivery time

- Low costs for printing in small batches.

- Allows you to print different information on a single batch of labels

Additional options for printing:

Cold and hot foil

If you want your product to be eye-catching and memorable, foil is just what you need. There are many colors and textures to choose from, so be sure to match your expectations.

Embossing

A molded image is an image printed on paper or cardboard, which is stamped onto the product without the use of colors. This gives a beautiful relief effect. It should always be borne in mind that the embossing passes over to the other side, so that the other side of the sheet is left out or molded.

Screen printing

Allows the product to highlight different design elements in an exclusive way.